Principle of heat preservation  The modern thermos flask was invented by the British physicist Sir James Dewar in 1892. At that time, he was working on a research project to liquefy gases, which could be liquefied at low temperatures, and he first needed to design a container that could isolate the gas from the outside temperature, so he asked the glass technician Berg to blow a double-layer glass container for him, coated the inner walls of the two layers with mercury, and then remove the air between the two layers to create a vacuum. This kind of vacuum bottle is also called "Du bottle", which can keep the liquid in it unchanged for a certain period of time regardless of cold and hot temperature.

The modern thermos flask was invented by the British physicist Sir James Dewar in 1892. At that time, he was working on a research project to liquefy gases, which could be liquefied at low temperatures, and he first needed to design a container that could isolate the gas from the outside temperature, so he asked the glass technician Berg to blow a double-layer glass container for him, coated the inner walls of the two layers with mercury, and then remove the air between the two layers to create a vacuum. This kind of vacuum bottle is also called "Du bottle", which can keep the liquid in it unchanged for a certain period of time regardless of cold and hot temperature.

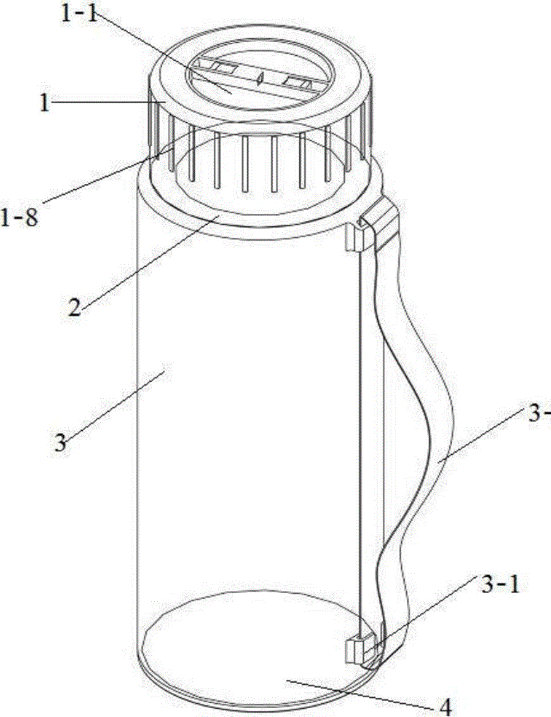

Because the thermos bottle is mainly used for hot water insulation in the home, it is also called a hot water bottle. The construction of a thermos flask is not complicated.

The middle is a double-layer glass bottle, between the two layers into a vacuum state, and silver or aluminum, the vacuum state can avoid heat convection, the glass itself is a bad conductor of heat, and the silver-plated glass can reflect the heat energy radiated from the inside of the container. Conversely, if a cold liquid is stored in the bottle, the bottle prevents heat from radiating into the bottle.

The stopper of a thermos flask is usually made of cork or plastic, both of which are also not easy to conduct heat. The shell of the thermos flask is made of bamboo, plastic, iron, aluminum, stainless steel and other materials, and the mouth of the thermos flask has a rubber gasket and a bowl-shaped rubber cushion at the bottom of the bottle, which are used to fix the glass gall to prevent collision with the shell.

The worst place for the thermal insulation and cold insulation function of the thermos flask is around the bottleneck, where the heat is mostly circulated by conduction. Therefore, the bottleneck is always shortened as much as possible during manufacturing, and the larger the capacity and the smaller the bottle mouth, the better

How stainless steel thermos flasks are kept warm

The thermos flasks are made of double-layer stainless steel tank structure, the middle layer is vacuumed to eliminate heat transfer and convection, and the inner tank is coated with copper foil or aluminum foil to produce specular reflection and reflect the radiation. Keep the temperature warm.

Related blogs

80% of human diseases are related to water, and drinking high-quality drinking water is beneficial for health and longevity.

administrator.2024-04-24

Fundamentally, water is the source of life, and we can't even live without drinking it. But staying well hydrated is also essential for our daily health and well-being.

administrator.2024-04-15

How stainless steel thermos flasks are kept warm

administrator.2024-03-12

Little Secrets in Drinking Water

administrator.2024-04-03

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian